Robotics Champions

By Maleeya Mickelson and Milan Riley

Science Academy is the proud home to a world-renowned Robotics Club! Our teams have received many awards over the years and have brought back multiple wins, not only from local VEX Robotics Competitions (VRC), but from State and even World competitions. This year has continued to showcase the many talents of our students with an especially successful season.

The 2022-2023 Robotics Teams consisted of between two to five members, who worked together on their planning and execution by meeting at least twice a week to get ready for competitions throughout the season. As part of their dedication to the Robotics Program and in preparation for their competitions, teams often met in Science Academy’s on-campus Robotics Lab after school on Tuesdays and Wednesdays. During that same time, advanced robotics mentors provided assistance to students as well.

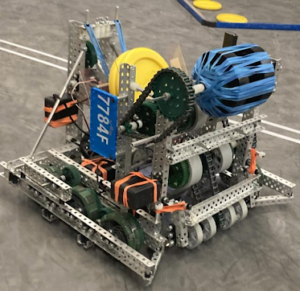

Example of 2023 VEX VRC robot

Example of 2023 VEX VRC robot

Each team strived to build a robot that could compete in all aspects of the game. Every year the game changes, meaning the teams have to create new robots. This year’s game, called “Spin Up”, challenged two alliances, Red and Blue, each made up of two teams. The game started off with a 15-second autonomous period — a period when the two teams used code already pre-made to score as many points as possible. The alliance who scored the most points during this time received a 10-point bonus. The game then moved onto a 1-minute and 45-second long driver control period, where alliances once again had to score as many points as possible. Different ways to score points included shooting discs into the high goal (5 points), getting discs into the low goal (1 point), or spinning the rollers on the field (10 points). During the last 10-seconds of the match, teams could release their robot’s expansions (often made out of string) in order to score even more points by covering the tiles on the field. Every tile the team covered at the end of the game scored them another 3 points.

The 2023 challenge arena

The 2023 challenge arena

Teams competed in many competitions this season. An overall win at one of the local competitions, as well as winning certain awards that vary from competition to competition could qualify them for the States competitions. At competitions, teams went through multiple rounds with randomly picked alliances in order to determine seeding for the elimination round. After a certain number of rounds, teams then chose their own alliances for playoffs and eliminations. Teams higher on the seeding chart received the chance to pick an alliance sooner. The 16 alliances created, consisting of a total of 32 teams, then went on to compete for the championship.

Teams also could have qualified for State competitions via another aspect of VEX Robotics Competitions known as Skills. At each competition, teams received six tries to score as many points as possible either autonomously or by driver control. They were allowed three tries for each method. Autonomous and driver control during Skills were very similar to during matches because the teams used the same methods to score points; however, teams did not have to deal with defense from their opponent or defending themselves because they were the only ones on the field.

Middle School Champions during the competition

Middle School Champions during the competition

Another large component of the competition focused on the creation and organization of the team’s engineering notebook. Throughout the season, teams recorded their progress and all the work they’ve done on their robots, from their first prototype to their final design after many adjustments and long hours of trial and error. The purpose of the notebook is to show the judges the team’s thinking, processes and their progress. Without a good engineering notebook, teams cannot win many of the awards.

This year, VEX held two State competitions, split into middle school and high school, for our region, one in San Diego and another in Los Angeles. Teams from the Science Academy won both competitions (3324U & 3324B), qualifying them for Worlds. Other teams also qualified for Worlds either by having a high score in Skills or by the following awards: Excellence Award, Design Award, Robot Skills Champions, Innovate Award, Amaze Award, Think Award, or Build Award.

Team 3324B at a state competition

Team 3324B at a state competition

The VEX Robotics World Championship was held in Dallas, Texas at the Kay Bailey Hutchison Convention Center Dallas from April 25 to May 5. The event was split into competitions for middle school and high school. Two of our high school teams competed from April 25 to April 27 and of our eight middle school teams participated from April 27 to April 29. Due to the large number of teams present at the World’s competition, VEX split the teams into different divisions. Within each division, each team participated in a mini competition, where the winners from each division advanced to the final elimination rounds in the so-called “Dome.” These rounds took place with thousands of people watching.

2023 Vex Robotics Competition

2023 Vex Robotics Competition

After a fierce competition between Science Academy’s Team 3324U (aka Supernova Team Hydra) and their alliance Shanghai’s Team 9123X against West Vancouver’s Team 10012W and their alliance Shanghai’s Team 9123C, Supernova Team Hydra and their alliance emerged triumphantly as the VEX VRC Middle School World Champions 2023! Despite being a first-year team, two eighth graders, Nicholas Mandreyka and Eero Wolfe, successfully created a robot worthy of a world championship. Congratulations to them!

The following Science Academy teams also won awards in their divisions as listed:

3324U Nicholas Mandreyka and Eero Wolfe Think Award

3324B Shivaan Nigam, Liam Cahill and Lily Kelsay Amaze Award

3324Y Aidan Limketkai, Gabe Cooper and Aaron Park Build Award

During the World’s competition, VEX also revealed the challenge for the 2023-24 season: Over Under. The goal of Over Under is to score as many points as possible by performing actions such as placing the game element (tri-balls) under goals or elevating the robot on a post at the end of the game.

Congratulations to all teams that participated in the 2022-23 VEX robotics season! Each and every team did a great job and has made the Science Academy very proud. A special congratulations to the members of 3324U, 3324B, and 3324Y for their accomplishments at the World Championship. Good luck to all teams competing in the 2023-24 season!

After the excitement of the World Championship, teammates Eero Wolfe and Nicholas Mandryka, the middle school winners of the 2023 VEX Robotics Competition, sat down with Milan Riley for an interview looking back over this momentous competition season:

1. What were your goals for this competition?

“Our goal for this competition was to win our division [500 teams are split into 6 divisions].”

2. What have you learned from past competitions and how are you putting that info to use now?

“What we have learned from past competitions was that ranking high before eliminations and alliance selection is important, as well as warming up before each match.”

3. What specific skills have you and your team been working on to prepare?

“Specific skills that our team has worked on to prepare was my driving because at high levels, robots are equally matched as they can score points at almost 100% efficiency and it comes down to the driving to determine who wins.”

4. What modifications have you had to make to your robot(s)?

“Some modifications that we have made to our robot was to have it shoot very fast so that when being defended, we can shoot all of our disks before being blocked. We also made sure that our expansion – we try to cover as many tiles as possible using string that is launched from the robot – does not fire out of the field so that we are not disqualified from the tournament.”

5. What were some highlights from the competition?

“Some highlights for the competition were of course winning it, but also after and during the competition when all of the teams were together having fun and supporting each other.”

6. Why do you think you guys did so well this year?

“Some reasons that we did so well this season was that we had great mentors and sister teams that helped us so much and motivated us to try so hard.”

7. What are you looking forward to working on in the future?

“We are looking forward next year to competing in high school with new members on the team and being able to help the new teams that were once us.”

8. What capabilities are you looking forward to the robotics world developing in the future in the competition world? What about in terms of real-world applications?

“As new technology like more efficient electronics become accessible, teams will be able to do even more and create amazing robots that can compete at levels unimaginable right now. VEX robotics takes a lot of real world robotics concepts and incorporates them into the competition, meaning that as technology becomes better, so will the robotics in the real world.”

The Perseverance Rover: A Personal Perspective

by Ryder Beeler

Touchdown! On February 18, 2021, the Perseverance Rover landed on Mars as millions of people watched the event all around the world. As I watched the landing, I was reminded of the time when I was seven years old. A friend of my parents, Ms. Jules Lee, worked for Jet Propulsion Laboratory (JPL) as a navigational engineer and she invited us to JPL for a visit and private tour. We saw the premises and even visited Mission Control, as well as what is known as the Clean Room. Engineers dressed in full body protective suits, caps, shoe coverings, gloves, and face masks that prevent even the smallest piece of dust or hair ruining sensitive instruments were working on a $2 billion spacecraft named Perseverance, which was set to launch some time in the next decade. And here we are: Perseverance got launched, successfully landed, and is already exploring Mars!

The Perseverance expedition has been widely covered in the news, but there are some aspects about Perseverance and Ingenuity that the public may not know about. I was honored to reconnect with our family’s friend, Jules Lee, who is one of the navigational engineers at JPL in Pasadena. I interviewed her and am very happy to be able to share some information with regards to the mission.

The main purpose of the mission is to see if there have been living organisms on the planet in the past or if they still exist in the present. Perseverance was stationed at Jezero Crater since it used to be a lake filled with water, which is required for life. It will take samples of the rocks in the ground, which will be stored in the rover until brought back to Earth. Once back, the samples will be tested for any water or remains of previously living organisms. Ingenuity will then be flying around the area surrounding the rover doing weather reports. Ingenuity is in its operations demo phase and is the first helicopter on Mars. Here is some further information from NASA on Ingenuity: https://www.nasa.gov/feature/jpl/6-things-to-know-about-nasas-ingenuity-mars-helicopter

As you now know, Perseverance and Ingenuity are the two main components of a rover program that were sent to Mars. However, did you know how Perseverance is linked to the next major mission or that the whole mission itself is much older than you think? Mrs. Lee stated that the Perseverance will play a major role in NASA’s next mission. The mission, which is not yet named, will be responsible for bringing the samples that Perseverance is currently collecting back to Earth. These samples will be used to determine if there was, or better yet now is, life on Mars. Perseverance didn’t just start in 2015 when it began to be built. The simple idea for the Perseverance was developed around the late 1990’s – early 2000’s. Approximately 15 years later, it had gained full attention from NASA and the build commenced. A little after that, the route for Perseverance was plotted, the spot of landing was chosen, and after the physical completion, multiple checks took place to ensure that the rover was in perfect condition.

In addition to some of the better known details, there are also some that do not receive as much coverage in the news: for instance, the fact that the United States wasn’t the only country involved in Perseverance. The mission was not just funded by and constructed solely here. Other space programs have contributed financial and material resources to the program where NASA / JPL would trade items and materials with space programs abroad, like Centro de Astrobiologia  Instituto Nacional de Tecnica Aeroespacial in Spain and Forsvarets Forskningsinstitutt in Norway. Secondly, communication between Earth and the rover sometimes faces serious challenges. Signals can be intercepted by a piece of space debris or a space rock. And this is particularly stressful for all the engineers at Mission Control during what is called “the seven minutes of terror,” which refers to the entry, descent and landing (EDL) phase of the rover. This is such an anxious time because events take place much quicker than the radio signals can reach Earth from Mars for communication. Rovers communicate with Earth directly, but with Perseverance, communication did not get turned on for a month or so, until all of its diagnostics and checkouts were done. The Mars orbiters, Odyssey, MRO and MAVEN, helped out relaying telemetry engineering data in near real time during Perseverance’s EDL on February 18th. For further information on NASA’s Mars Program, check out their website: https://mars.nasa.gov/#mars_exploration_program/1

Instituto Nacional de Tecnica Aeroespacial in Spain and Forsvarets Forskningsinstitutt in Norway. Secondly, communication between Earth and the rover sometimes faces serious challenges. Signals can be intercepted by a piece of space debris or a space rock. And this is particularly stressful for all the engineers at Mission Control during what is called “the seven minutes of terror,” which refers to the entry, descent and landing (EDL) phase of the rover. This is such an anxious time because events take place much quicker than the radio signals can reach Earth from Mars for communication. Rovers communicate with Earth directly, but with Perseverance, communication did not get turned on for a month or so, until all of its diagnostics and checkouts were done. The Mars orbiters, Odyssey, MRO and MAVEN, helped out relaying telemetry engineering data in near real time during Perseverance’s EDL on February 18th. For further information on NASA’s Mars Program, check out their website: https://mars.nasa.gov/#mars_exploration_program/1

When I think back to the day that I visited JPL Mission Control and witnessed the engineers’ work on NASA’s next project, I had no idea that this would be the Perseverance as we know it now. Perseverance is currently exploring a planet 190.09 million miles from Earth. We can expect the next mission to launch within a decade. How exciting it will be to witness another interplanetary touchdown!

Read More

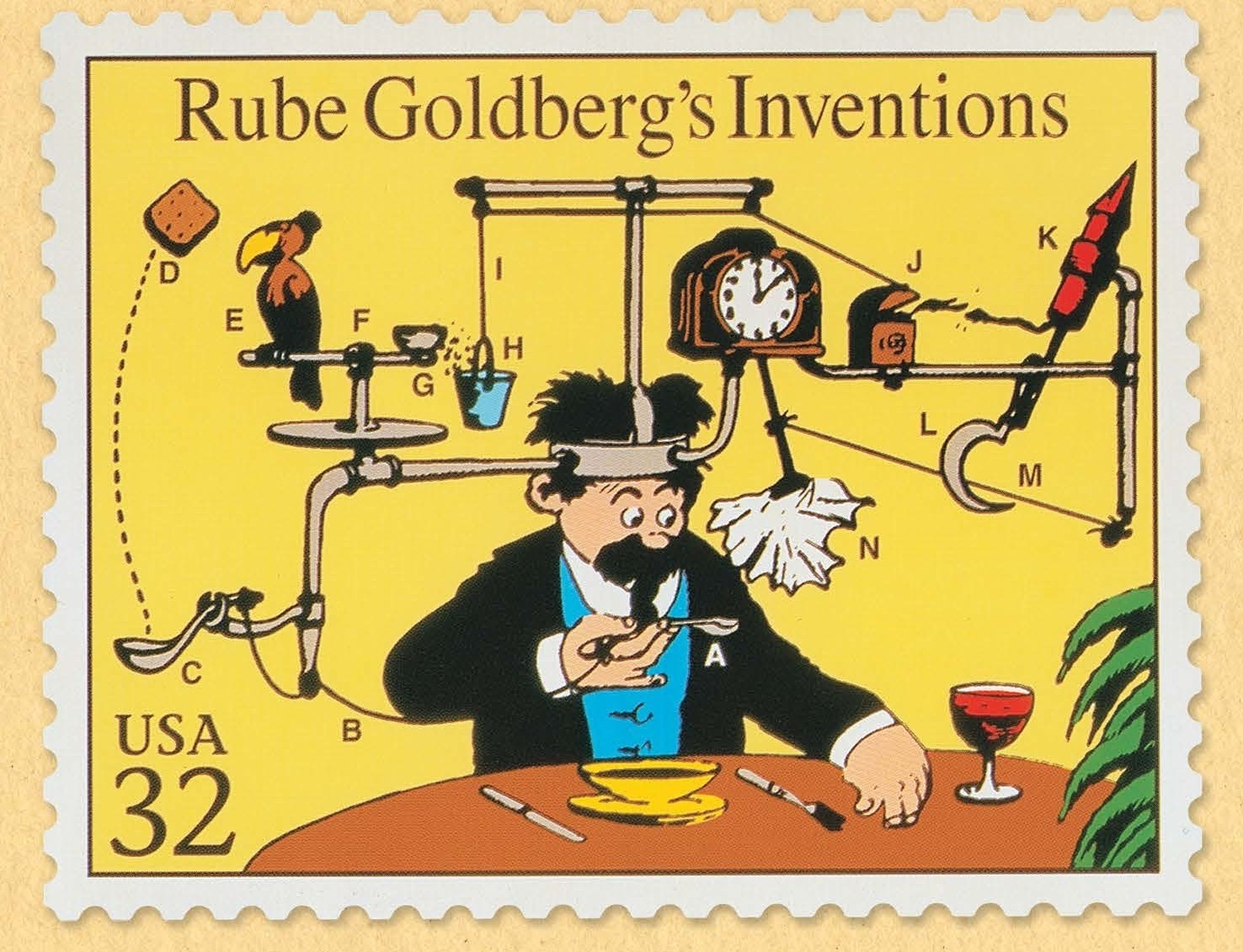

Rube Goldberg Machines Compilation

by Suren Grigorian and Daniel Svediani

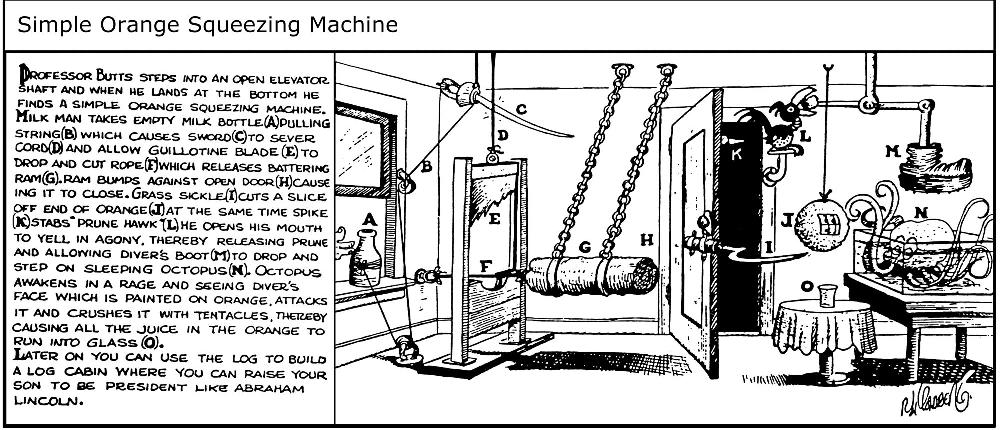

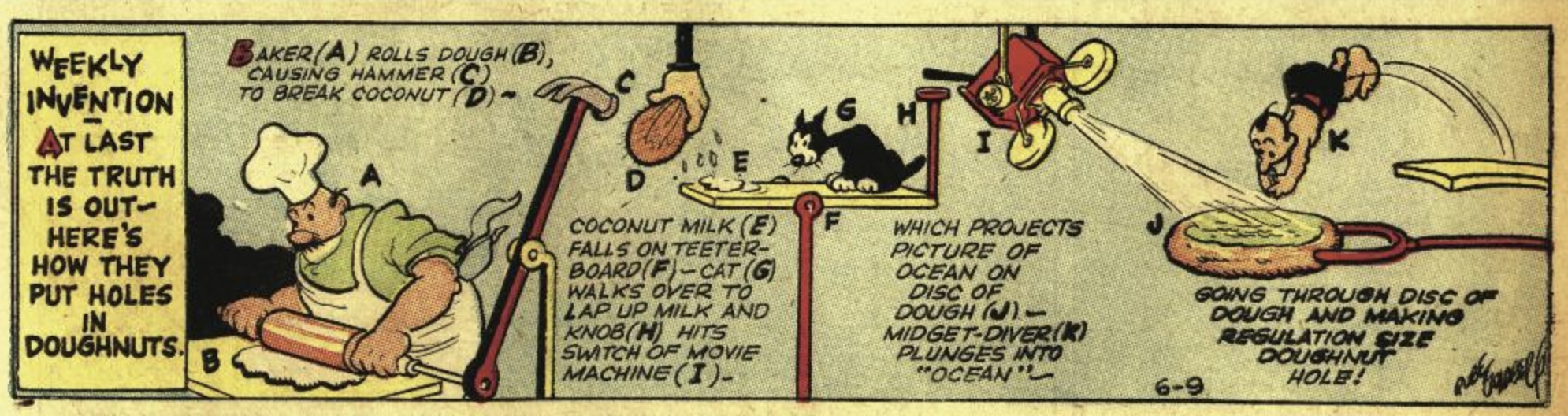

The name of Rube Goldberg has become synonymous with the word “mechanism,” with his machines connoting images of complex chain reactions which accomplish a minor and relatively routine task at their end. However, the development of these machines began upon the drawing board, as the original Rube Goldberg developed a reputation for these devices through his artistic precocity.

Rube Goldberg, known originally as Reuben Lucius Goldberg, was born on July 4, 1883, to a San Francisco police and fire commissioner and a member of a Reform Jewish congregation. During his childhood, he displayed remarkable talent in the tracing of illustrations. As he grew up, his inclination toward the arts became apparent, but he was encouraged on a path of engineering by his father, graduating from the University of California, Berkeley in 1904. However, his presence in the engineering community did not last long, as he decided to pursue his original inclination for the arts. He joined the San Francisco Chronicle and the San Francisco Bulletin, gaining cartoon syndication with several newspapers.

By 1915, he became known as America’s most popular cartoonist. His most popular comic strip was The Inventions of Professor Lucifer Gorganzola, which brought him fame and is the one that we all associate with Rube Goldberg. The strip exhibited comically intricate inventions created by a Professor Butts, and these devices would later become known as Rube Goldberg machines. Later, he created a series of seven short animated films depicting the humorous aspects of everyday life.

Check out the awesome student-made Rube Goldberg machine shorts from Mr. Bradfield’s MakerSpace classes in the attached compilation above!

Original Rube Goldberg cartoons:

Read More

Zyg Ramsay: 3D Printing Hero

by Ms. Kincaid and David Tang

I’m sure there are many of us who read about what’s happening in the news and see how hard healthcare and frontline workers are working to keep us safe, and we wonder, “What can I do to help?” Well, 8th grader Zyg Ramsay went ahead and decided to do something about it. He saw the challenges that healthcare workers were having getting all the Personal Protective Equipment, or PPE, they needed. With a highly contagious virus like SARS-CoV-2, doctors, nurses and others must have not only masks and full gowns, but also face shields to prevent the microdroplets that could carry the virus from coming in contact with their faces. Zyg saw that Budmen Industries was looking for volunteers to help flatten the curve and protect healthcare workers by using their home 3D printers to print these face shields.

As he explains, “I was fiddling around on the internet and found the Budmen website that contains 3D printing files. You register to become a producer. They didn’t tell me what to do so I just printed one to see how it worked. I thought, “Once they email me to start printing stuff I will.” I got an email from Budmen saying there was an L.A. location, with somebody putting it together in the L.A. area, so I signed up for that. I didn’t have to design the file; you don’t code the printer’s movements, there’s a program that takes a 3D image and converts it into text which the printer follows.”

MS KINCAID: What material do you use to print the face shields?

ZYG: I use PLA [polylactic acid] for the face shields, which is a plastic made from corn, so it is biodegradable. My printer melts it at 200⁰ C and prints each of the 30 layers layer by layer, printing a complete face shield in 2 hours. There are two things I print for it. One is the actual shield in front of the face, and the other is the strap lock that keeps the elastic in place.

MS KINCAID: About much does it cost to make each one?

ZYG: I calculated it at one point, I think it’s around 12¢ of material for each one. I’ve printed 59 shields, so almost 3 kg of plastic.

I asked Zyg how he got into 3D printing. “About 2 years ago, I read about 3D printing in MAKE: magazine. My first printer cost around $200, but it was only able to print up to 4 cubic inches. I got a larger one for Christmas that can print up to 11 cubic inches.”

Our interview continued:

MS KINCAID: What else are you working on?

ZYG: Right now I’m working on making two drones. One is a tricopter with three propellers and servo motors to turn the propellers. From what I have read, it’s is much more stable and easier to control, but for some reason it’s less common than the quadcopter, the normal drone with a

MS KINCAID: Why do you think that the tricopter is better than the quadcopter?

ZYG: The tricopter doesn’t turn by slowing down one propeller and speeding another like the quadcopter, it turns the servo. It also doesn’t lean when it moves to the side, it stays in place, which helps people with cameras on their drones.

I’m also working on a minor soldering project. My mom bought a PCB for me, which is a superthin circuit board, and I solder super tiny electronic pieces onto the PCB with solder, which is just super easy-to-melt metal that conducts electricity.

MS KINCAID: Are you just experimenting to see if you can solder that small or are you actually trying to modify the board?

ZYG: I’m just trying to solder that small. Usually I solder bigger things but it has the soldering pads to attach components to it. The last project I’m working on is my MakerSpace project, which is the prosthetic hand controlled by muscle signals.

MS KINCAID: Can you tell us about that?

ZYG: Basically it works with 5 servos connected to string that attaches to each of the 3D printed fingers. When the servo turns one way, the finger closes, and when the servo turns the other way, the finger opens. I control it using muscle signals with a control board connected to a microcontroller like an Arduino. The part connected to the muscle uses EMG [electromyography] to measure difference in electricity between different points on the arm. It uses this EMG to figure out if the person is trying to flex or relax. This works because muscles use actin and myosin fibers, triggered by electrical impulses and powered by ATP.

MS KINCAID: What is your goal?

ZYG: I want to make a very cheap prosthetic hand where you can move each finger independent of each other. Right now your options are: a cheap one that closes all fingers at a time, which is bad for writing or holding circular objects, or an independent-digit expensive hand for around $10,000. Mine would be $150-200 but with independent digits. I would want to program patterns into it for set hand positions because it’s hard to program in each muscle.

MS KINCAID: If this is meant for someone without those muscles? Where would the signals come from?

ZYG: Right now, I control it via my forearm. This is designed for somebody who has no wrist, but still retains most of the forearm, so you can still use the muscles of the forearm. Closing and opening the hand uses muscles in the forearm, not the hand or wrist. Just using the forearm is a bit harder, but you can learn to do it. Studies have shown that with training, you can learn to use your brain to control a whole prosthetic arm.

MS KINCAID: That is cool! Would the stickers with wire be attached to your temples, then?

ZYG: You wouldn’t use the stickers, you would use the headset that goes over your head and measures alpha brain waves. You can’t really control an arm with that outside of the lab because you would have to get something implanted in your brain to control the arm, and you can’t do that outside of the laboratory.

MS KINCAID: So I guess that’s where we are today, and we’ll keep moving forward with the technology. Thanks Zyg, I feel like I learned a lot today!

ZYG: Thanks, you too! Bye!

As Mr. Bradfield, Zyg’s MakerSpace teacher commented, “It was inspiring to see Zyg applying the design and engineering principles he learned in class to a real-world problem.” It is inspiring to see our students take what they learn and help make the world a little bit better!

If you are interested in registering to 3D print face shields, learn more by clicking below:

Read More